Have you ever felt confused about titanium dioxide (TiO2) and titanium oxide (Ti)? I definitely know that feeling! Let's clear it up together, okay?

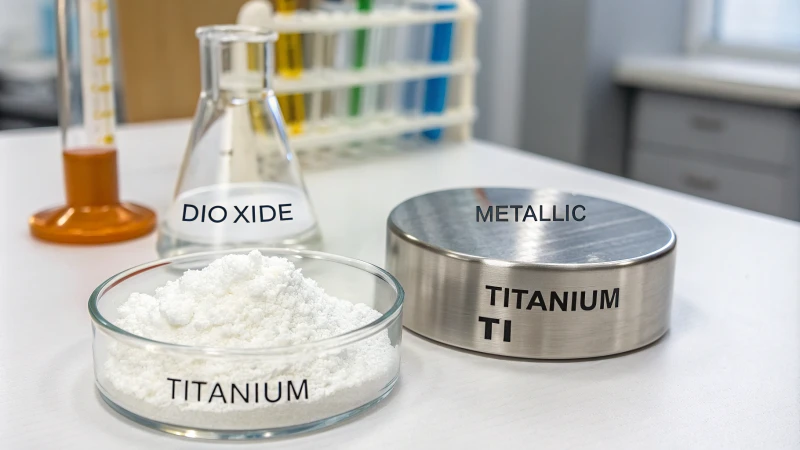

Titanium dioxide (TiO2) and titanium oxide (Ti) are different materials. They have unique chemical traits. TiO2 often appears as a pigment in paints. People use it for its stability and ability to block UV light. Ti is metallic titanium. It is famous for its strength. It also resists corrosion. Titanium is very strong.

When I first explored titanium compounds, I felt really surprised. A simple difference led to many uses. Titanium dioxide (TiO2) resembles a reliable friend. It is stable and often found in paints and cosmetics. Its bright, white color and UV-blocking ability are important. This compound is very popular. Titanium oxide (Ti) is like an adventurous friend. It excels in extreme conditions. Its strength and resilience are well-known, especially in aerospace and medical areas. Understanding these differences removed my confusion. I now appreciate their unique roles in our daily lives.

Titanium dioxide (TiO2) is a pigment used in paints.True

TiO2 is widely utilized in the paint industry for its stability and UV-blocking properties.

Titanium oxide (Ti) is the same as titanium dioxide (TiO2).False

Titanium oxide (Ti) refers to metallic titanium, distinct from TiO2 compound.

What Makes Titanium Dioxide (TiO2) Such a Unique Compound?

Have you ever thought about why Titanium Dioxide (TiO2) appears so much in our daily lives? Its special chemical traits bring many benefits in different fields. Let's explore what gives TiO2 its unique value!

Titanium Dioxide (TiO2) is very important in many industries. It is very stable and safe. It also has unique optical properties. TiO2 absorbs UV light and has photocatalytic abilities. It is essential in products like paints, cosmetics and catalysts.

Overview of Titanium Dioxide (TiO2)

Titanium Dioxide, also known as TiO2, has impressive features. Its basic chemical setup gives it many useful qualities, making it very valuable in many fields. I often tell friends about TiO2’s ability to stay stable in high heat and resist rust, which helps it succeed where other things would fail.

One of the remarkable aspects of TiO2 is its stability at high temperatures and resistance to corrosion. This stability is crucial in environments where reactive substances are present. For instance, in photocatalytic applications1, TiO2 acts effectively to break down pollutants when exposed to UV light.

Crystal Forms of TiO2

I found it exciting that TiO2 forms in three different crystal shapes: rutile, anatase, and brookite. Each type has special characteristics:

| Crystal Form | Properties | Applications |

|---|---|---|

| Rutile | High refractive index, strong UV absorption | Pigments in paints and coatings |

| Anatase | Better photocatalytic activity | Environmental remediation |

| Brookite | Less stable, rare | Niche applications in research |

In my industry experience, I noticed rutile shines because of its great opacity and strength, especially in making pigments. Anatase often serves well in light-driven applications. It is amazing how each form meets particular needs!

Chemical Reactions Involving TiO2

I am truly thrilled by TiO2's wonderful response to light-driven chemical reactions. I saw it create hydroxyl radicals under UV light, which break down harmful organic pollutants. This power aids environmental cleanup. It acts as a solid partner in our fight against pollution. This property is harnessed in environmental cleanup processes2 and water treatment technologies.

Non-Toxic and Biocompatible

A comforting fact about TiO2 is its non-toxic nature. Knowing it is safe to touch reassures me, as it is widely used in sunscreens and lotions. I recall putting sunscreen on my kids, feeling confident TiO2 protected their skin from harmful UV rays. It meant everything.

TiO2 is classified as non-toxic and biocompatible, making it ideal for use in products that come into contact with humans. For instance, it is commonly found in cosmetics such as sunscreens and lotions due to its UV-blocking capabilities.

Conclusion on Industrial Applications

In many fields like paint, plastics, and cosmetics, TiO2 becomes a key ingredient due to its unique properties. It involves meeting strict safety standards while not just improving product performance but also ensuring consumer confidence through safety profiles.

Understanding these chemical properties allows makers to improve their products' quality. If you wonder about TiO2's effect on product formulas, researching more can be very eye-opening - it probably won't disappoint you! For more insights into specific uses, you might consider exploring the impact of TiO2 on product formulations3.

TiO2 is non-toxic and biocompatible for human use.True

Titanium Dioxide is safe for use in products like cosmetics due to its non-toxic nature, ensuring consumer safety and confidence.

Rutile is the least stable form of Titanium Dioxide.False

Among the three forms of TiO2, rutile is the most stable, contrary to this claim which is false.

In What Industries Is Titanium Oxide (Ti) Commonly Used?

Have you ever wondered how crucial titanium oxide (Ti) really is in our daily lives? This unique material plays a very big role in many industries. Let's explore which sectors truly enjoy the advantages of this amazing substance.

Titanium oxide has many uses. The aerospace industry uses it because it is strong. Medicine professionals value it because it is biocompatible. It provides opacity in coatings and color stability in plastics. Its versatility is very useful in many sectors. So, titanium oxide is important in different fields.

Aerospace Industry

In aerospace, titanium oxide acts as a hidden hero. The strong yet light nature and rust resistance make it crucial for building aircraft parts. Engineers often use titanium alloys in turbine engines to handle extreme heat and pressure. Flying at 30,000 feet with such reliable technology gives me comfort and safety.

Medical Applications

In medicine, titanium oxide shines differently. Its safe use with human tissues makes it perfect for implants and prosthetics, like hip replacements or dental inserts. I admire how titanium dioxide improves lives - granting people mobility and self-assurance. It’s also in sunscreens and cosmetics, offering protection against harmful UV rays. Imagine using sunscreen knowing it contains a material that protects your skin and helps save lives!

Coatings and Paints

In paints and coatings, titanium dioxide is very important. Its great opacity and whiteness let everything from homes to cars look stunning. I’ve seen how durable finishes resist fading, letting us enjoy our favorite colors without worry.

| Industry | Application | Properties Utilized |

|---|---|---|

| Aerospace | Aircraft components | Strength, corrosion resistance |

| Medical | Implants and prosthetics | Biocompatibility |

| Coatings & Paints | Pigment in paints | Opacity, UV protection |

Plastics and Polymers

In the plastic world, titanium dioxide adds stability and opacity to colors. Aesthetics are crucial in consumer products. Packaging and household items look great thanks to TiO2.

Environmental Protection

Titanium dioxide also helps in environmental protection! It acts as a photocatalyst, breaking down pollutants when UV light hits it. This compound helps clean air and water, making our world a little brighter.

Construction Materials

Finally, titanium oxide appears in construction materials like cement and tiles. It not only increases durability but also improves appearance with better whiteness and shine in building facades.

Titanium oxide is commonly used in aerospace components.True

Its strength-to-weight ratio and corrosion resistance make titanium oxide essential for aircraft manufacturing, especially in turbine engines.

Titanium oxide is ineffective as a UV-blocking agent in cosmetics.False

Contrary to this claim, titanium dioxide is renowned for its effective UV-blocking properties in sunscreens and cosmetic products.

What Are the Safety Considerations for Using Titanium Compounds?

At first, I explored titanium compounds and titanium dioxide. I was surprised. People use these in many everyday products. These compounds appear in products around us very often. Many daily items contain them. But using them also brings responsibility. It's important to consider safety aspects. Let's look closely at these safety considerations.

When working with titanium compounds like titanium dioxide, people should think about health risks from breathing them in. They must follow proper handling practices. Awareness of environmental impacts is crucial. Everyone must follow safety protocols. This way, we use these materials safely. Responsible use is very important.

Understanding Titanium Compounds and Their Uses

Titanium compounds, especially titanium dioxide (TiO₂), are prevalent in various industries, including paints, cosmetics, and pharmaceuticals. While TiO₂ is regarded as safe and non-toxic, there are still safety considerations that need to be addressed when handling these materials. To ensure safe usage, it’s crucial to understand the specific properties of titanium compounds.

For instance, in paint manufacturing, where titanium dioxide serves as a pigment, precautions should be taken to minimize inhalation of dust during processing. Safety measures include wearing appropriate personal protective equipment (PPE) such as masks and goggles. Learn more about PPE4 to ensure you’re adequately protected.

Potential Health Risks

While titanium dioxide is generally considered safe, recent studies have raised concerns regarding its inhalation as fine particles may pose respiratory risks. The International Agency for Research on Cancer (IARC) has classified it as possibly carcinogenic in humans when inhaled in high concentrations. Therefore, manufacturers should enforce strict guidelines on the handling and ventilation systems in areas where titanium dioxide is processed.

Safe Handling Practices

To mitigate risks associated with titanium compounds, companies should implement safety protocols that include:

- Conducting Risk Assessments: Regular assessments can help identify potential hazards when using titanium compounds.

- Proper Training: Employees should receive training on the safe handling of titanium compounds, particularly in environments where exposure levels may be higher.

- Use of Engineering Controls: Implementing ventilation systems can reduce airborne concentrations of titanium dust. Explore ventilation solutions to improve workplace safety.

| Safety Protocol | Description |

|---|---|

| Conduct Risk Assessments | Identify hazards associated with titanium use. |

| Provide Training | Ensure employees understand safe handling practices. |

| Install Ventilation | Reduce airborne titanium levels during processing. |

Environmental Considerations

The environmental impact of titanium compounds should also not be overlooked. Proper disposal methods for waste products containing titanium must be established to prevent soil and water contamination. Utilizing recycling programs can help minimize waste and promote sustainability in operations.

Conclusion

In my experience, understanding titanium compound safety is vital. Safe practices and environmental responsibility let us enjoy these remarkable materials while staying protected and safeguarding our surroundings.

Titanium dioxide is completely non-toxic and poses no risks.False

While generally considered safe, titanium dioxide can pose respiratory risks if inhaled in high concentrations, thus it is not entirely non-toxic.

Proper ventilation is essential when handling titanium compounds.True

Implementing ventilation systems helps reduce airborne concentrations of titanium dust, ensuring safer working conditions during processing.

How Do the Manufacturing Processes of TiO2 and Ti Differ?

Do you ever think about how the materials we use every day are created? Knowing the differences between the ways TiO2 and Ti are produced really helps you understand their important roles in many industries.

Titanium dioxide (TiO2) and titanium (Ti) have different ways of being produced. The main difference lies in their chemical processing. TiO2 comes from sulfate or chloride processes. This means it uses chemicals like sulfate or chloride to be produced. On the other hand, titanium depends on Kroll or Hunter methods. These are distinct techniques for producing titanium.

Overview of Manufacturing Processes

The manufacturing processes for titanium dioxide (TiO2) and titanium (Ti) differ significantly, largely due to their distinct chemical properties and desired applications. Let's explore these processes in detail.

Titanium Dioxide (TiO2) Production Methods

TiO2 is primarily produced using two methods: the sulfate process and the chloride process. Each method has unique steps and outputs that cater to specific industrial needs.

-

Sulfate Process: This traditional method involves the digestion of titanium ore (like ilmenite) with sulfuric acid. The key steps include:

- Digestion: Ore is mixed with sulfuric acid to produce titanium sulfate.

- Hydrolysis: Water is added to precipitate hydrated titanium dioxide.

- Calcination: The hydrated titanium dioxide is heated to remove water, resulting in TiO2.

-

Chloride Process: This more modern and environmentally friendly method uses chlorine gas to produce titanium tetrachloride (TiCl4) from titanium ores. The process includes:

- Chlorination: Titanium ore is reacted with chlorine at high temperatures to form TiCl4.

- Purification: Impurities are removed through distillation.

- Oxidation: TiCl4 is oxidized at high temperatures to produce high-purity TiO2.

These processes highlight the differences in chemical reactions and inputs necessary for producing TiO2, which can influence its end-use applications in industries like paints and coatings.

Titanium (Ti) Production Methods

The production of titanium metal involves a different set of processes, primarily focusing on the extraction and reduction of titanium from its ores, typically rutile or ilmenite.

-

Kroll Process: The most widely used method for producing titanium metal today:

- Chlorination: Similar to the chloride process for TiO2, titanium ores are converted to TiCl4.

- Magnesium Reduction: TiCl4 is reduced using magnesium in an inert atmosphere, producing titanium sponge.

- Melting: The sponge is melted in a vacuum or argon atmosphere to form ingots.

-

Hunter Process: An alternative method, less common than the Kroll process, involves:

- Carbothermic Reduction: Titanium oxide is reduced with carbon at high temperatures, producing a lower purity titanium metal.

- Refining: The metal may require further refining to achieve desired specifications.

The choice of production method affects the properties of the final titanium product, including its mechanical strength and corrosion resistance, making these distinctions critical for specific applications in aerospace and medical fields.

Comparison Table of Production Processes

| Property | Titanium Dioxide (TiO2) | Titanium (Ti) |

|---|---|---|

| Primary Processes | Sulfate and Chloride | Kroll and Hunter |

| Input Materials | Ilmenite, Rutile | Rutile, Ilmenite |

| Final Products | High-purity TiO2 | Titanium sponge or ingots |

| Applications | Pigments, UV blockers | Aerospace, Medical implants |

As seen in the table above, the distinct manufacturing processes lead to varied applications and properties for TiO2 and Ti, highlighting their importance in different industries.

For further insights into this topic, you may want to explore advanced manufacturing techniques5 or check out material properties of titanium6.

TiO2 is produced using sulfate and chloride processes.True

The primary methods for producing titanium dioxide are the sulfate and chloride processes, each with distinct steps and applications.

Titanium is made exclusively through the Kroll process.False

While the Kroll process is widely used for titanium production, the Hunter process is also a viable method, though less common.

Conclusion

Titanium dioxide (TiO2) serves as a pigment in various industries, while titanium oxide (Ti) is valued for its strength and corrosion resistance in aerospace and medical fields.

-

Discover in-depth information about TiO2's chemical properties, applications, and benefits in different industries by clicking this link. ↩

-

Learn how different crystal forms of TiO2 affect its applications by visiting this link. ↩

-

Explore detailed industrial applications of Titanium Dioxide in coatings and plastics through this informative link. ↩

-

This link provides detailed insights into the proper use of PPE while working with titanium compounds, enhancing your safety measures. ↩

-

This link provides in-depth explanations of sulfate and chloride processes crucial for understanding TiO2 manufacturing. ↩

-

Explore the Kroll and Hunter processes for titanium production, essential for comparing it with TiO2 manufacturing. ↩