As global awareness of air pollution rises, the need for effective exhaust gas treatment technologies becomes crucial.

TiO2 is used in exhaust gas treatment primarily as a support material for denitration catalysts. These catalysts help reduce nitrogen oxides in emissions from power plants, chemical factories, and vehicles by enhancing catalytic reactions that convert harmful gases into harmless substances.

While TiO2’s function as a catalyst support is well-known, its broader implications for sustainable practices and air quality improvement are substantial. Let’s delve deeper into how this remarkable material contributes to pollution control and what makes it indispensable in modern exhaust treatment systems.

[claim claim=”TiO2 is the main catalyst in exhaust gas treatment systems.” istrue=”false” explanation=”TiO2 serves as a support material, not the main catalyst, in these systems.”]

What Makes TiO2 an Effective Catalyst in Exhaust Treatment?

Discover the role of TiO2 as a powerful catalyst in modern exhaust treatment systems.

TiO2 is an effective catalyst in exhaust treatment due to its high surface area, chemical stability, and ability to withstand harsh conditions, enabling it to facilitate the conversion of nitrogen oxides into harmless gases efficiently.

The Role of Surface Area in Catalysis

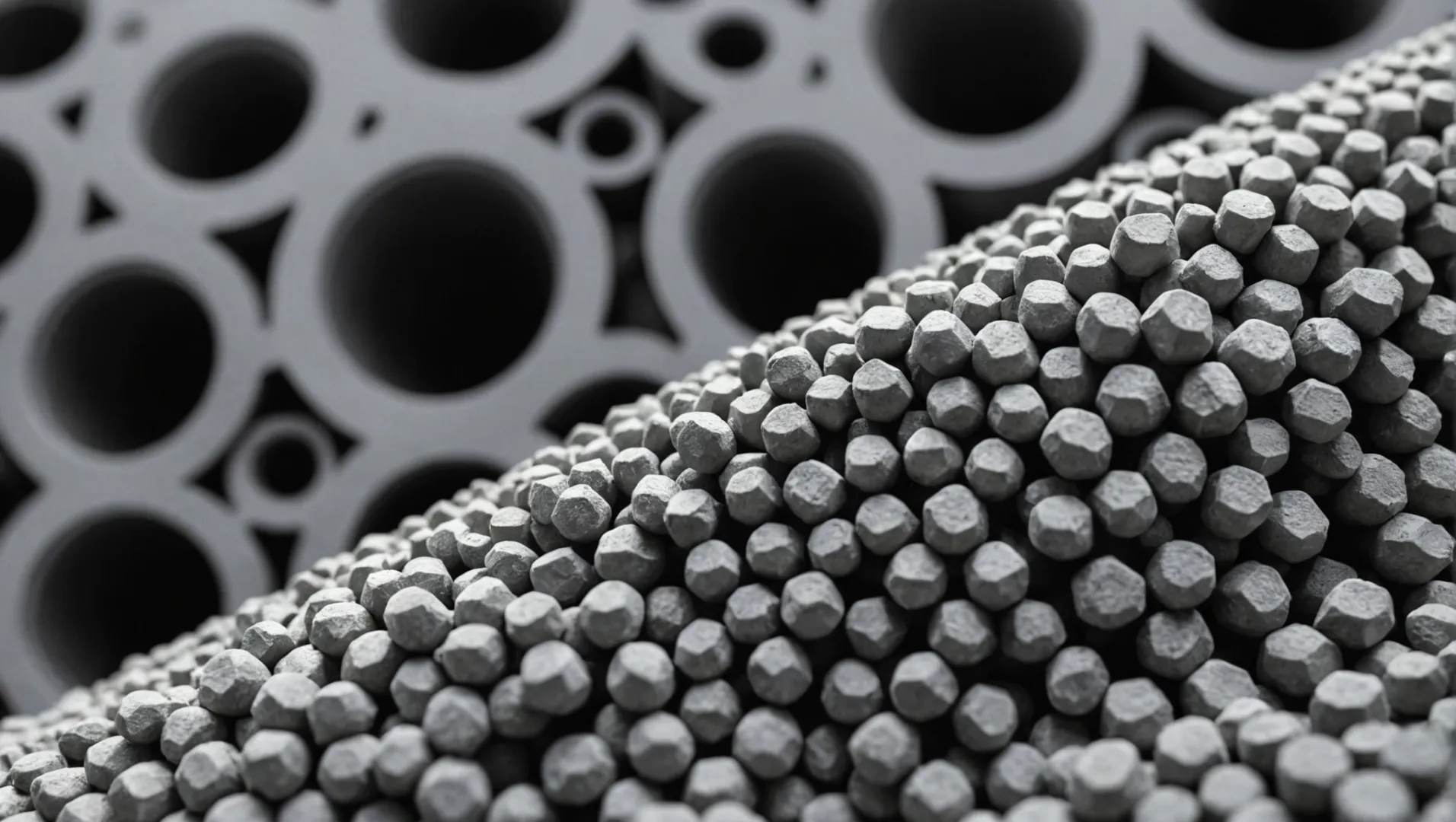

One of the primary reasons TiO2 excels in exhaust treatment is its large specific surface area. This characteristic significantly enhances its catalytic activity by providing more active sites for reactions to occur. The greater the surface area, the more opportunities there are for nitrogen oxides to interact with the catalyst, leading to increased efficiency in reducing these pollutants.

Chemical Stability and Resistance

TiO2 is known for its robust chemical stability, which allows it to withstand the harsh conditions often found in exhaust systems. This stability ensures that the catalyst maintains its effectiveness over time, even when exposed to high temperatures and corrosive gases. Moreover, its good resistance to sulfur compounds commonly present in emissions makes it an ideal choice for exhaust treatment applications.

Application Across Diverse Industries

Due to these advantageous properties, TiO2 is extensively used across various industries. Power plants, chemical factories, and vehicle manufacturing heavily rely on TiO2-based catalysts for emission control. For instance, denitration catalyzers1 incorporating TiO2 are crucial in reducing nitrogen oxides emissions in power plants.

Integration in Modern Vehicles

In the automotive industry, TiO2’s role extends beyond traditional applications. It is a key component in modern emission control systems, ensuring vehicles comply with stringent environmental regulations. By enhancing the reduction of harmful gases, TiO2 helps manufacturers meet standards while promoting sustainability.

The integration of TiO2 in exhaust systems exemplifies a blend of innovation and necessity, contributing significantly to pollution reduction and cleaner air quality.

[claim claim=”TiO2 has a large specific surface area.” istrue=”true” explanation=”TiO2’s large surface area enhances catalytic activity by providing more active sites.”]

[claim claim=”TiO2 is ineffective in high-temperature conditions.” istrue=”false” explanation=”TiO2 is chemically stable and withstands high temperatures, maintaining effectiveness.”]

How Does TiO2 Contribute to Reducing Nitrogen Oxides?

Uncover the pivotal role of TiO2 in cutting down nitrogen oxides from emissions.

TiO2, or titanium dioxide, acts as a vital support material in denitration catalysts, which are crucial for reducing nitrogen oxides in emissions. This process involves catalyzing the conversion of harmful nitrogen oxides into nitrogen and water, making emissions less toxic.

The Role of TiO2 in Catalytic Reduction

TiO2 serves as an essential component in the catalytic reduction of nitrogen oxides (NOx). Its primary function is to support the active catalytic materials that directly interact with NOx, such as vanadium pentoxide (V2O5) or tungsten trioxide (WO3). By providing a high surface area and stable structure, TiO2 enhances the catalyst’s efficiency2, ensuring prolonged activity and durability even in harsh conditions.

Mechanism of NOx Reduction

The reduction process generally follows the Selective Catalytic Reduction (SCR) method, where ammonia (NH3) is used as a reducing agent. The reaction typically proceeds as follows:

$$\text{4NO + 4NH}_3 + \text{O}_2 \rightarrow \text{4N}_2 + \text{6H}_2\text{O}$$

This reaction showcases how harmful NOx gases are converted into nitrogen (N2) and water (H2O), substances that are naturally present and harmless.

Advantages of Using TiO2

1. Resistance to Sulfur Compounds: TiO2-based catalysts demonstrate remarkable resistance to poisoning by sulfur compounds, which are common in industrial exhaust gases. This feature ensures that the catalysts remain effective over longer periods.

2. Stability Under High Temperatures: Industrial processes often involve high temperatures, and TiO2’s stability ensures that catalytic reactions can proceed without degradation.

Application in Various Industries

The use of TiO2-based catalysts extends beyond power plants to include:

- Chemical Factories: Where NOx is a byproduct of chemical synthesis processes.

- Oil Refineries: Which emit significant levels of NOx during refining processes.

- Vehicle Exhaust Systems: Where TiO2 supports catalysts in emission control systems3.

Future Prospects and Innovations

Researchers are continuously exploring new ways to enhance the efficiency of TiO2 in catalytic processes. Innovations like doping TiO2 with other metals or using it in novel composite materials could further increase its capacity to reduce NOx effectively. Such advancements promise to solidify TiO2’s role in combatting air pollution across diverse sectors.

[claim claim=”TiO2 enhances the efficiency of denitration catalysts.” istrue=”true” explanation=”TiO2 provides a high surface area and stable structure, boosting catalyst activity.”]

[claim claim=”SCR uses methane as a reducing agent for NOx reduction.” istrue=”false” explanation=”SCR typically uses ammonia (NH3) as the reducing agent, not methane.”]

What Industries Benefit Most from TiO2-Based Catalysts?

Titanium dioxide catalysts are revolutionizing various sectors by improving emissions and enhancing environmental safety.

Industries such as power generation, chemical manufacturing, oil refining, and transportation benefit significantly from TiO2-based catalysts. These catalysts aid in reducing nitrogen oxides, which are major pollutants, thus supporting compliance with stringent environmental regulations and promoting cleaner production processes.

Power Generation

In power plants, particularly those relying on fossil fuels, emissions of nitrogen oxides (NOx) are a major concern due to their role in forming smog and acid rain. TiO2-based catalysts provide an effective solution by facilitating the selective catalytic reduction (SCR) of NOx into nitrogen and water. This process not only reduces emissions4 but also helps power plants meet stringent environmental standards.

Chemical Manufacturing

The chemical industry heavily relies on TiO2-based catalysts to control emissions during various production processes. These catalysts are used in the treatment of flue gases, ensuring that harmful nitrogen oxides are minimized. By integrating TiO2 catalysts, chemical manufacturers can maintain high production efficiency while reducing their environmental footprint.

Oil Refining

Oil refineries generate significant NOx emissions during the combustion processes involved in refining crude oil into usable products. The application of TiO2-based catalysts in these settings is crucial for effective exhaust gas treatment. By converting NOx into less harmful substances, these catalysts ensure compliance with environmental regulations and enhance overall operational sustainability.

Transportation Sector

The transportation industry, including automotive and marine sectors, faces increasing pressure to reduce emissions. TiO2-based catalysts are integral to vehicle emission control systems, where they assist in breaking down NOx emissions in exhaust gases. This technology is vital for manufacturers aiming to meet global emission standards and improve air quality.

Industrial Benefits Overview

| Industry | Benefit from TiO2 Catalysts |

|---|---|

| Power Generation | NOx reduction through SCR |

| Chemical Manufacturing | Emission control in flue gas treatment |

| Oil Refining | Conversion of NOx during refining |

| Transportation | Vehicle emission control systems |

By employing TiO2-based catalysts, these industries not only contribute to a cleaner environment but also improve their efficiency and sustainability5. This dual benefit underscores the essential role of titanium dioxide in modern industrial practices.

[claim claim=”TiO2 catalysts reduce NOx in power plants.” istrue=”true” explanation=”TiO2-based catalysts facilitate SCR, reducing NOx emissions effectively.”]

[claim claim=”Oil refineries use TiO2 catalysts for CO2 reduction.” istrue=”false” explanation=”TiO2 catalysts are primarily used for NOx reduction, not CO2.”]

How Does TiO2 Enhance Vehicle Emission Control Systems?

Titanium dioxide (TiO2) plays a vital role in improving the efficiency of vehicle emission control systems.

TiO2 enhances vehicle emission control systems by serving as a support material for denitration catalysts, which are crucial in converting nitrogen oxides into harmless substances, thus reducing air pollution.

Understanding the Role of TiO2 in Catalytic Converters

In vehicle emission control systems, TiO2 is primarily used in catalytic converters, where it acts as a support material for catalysts like vanadium pentoxide. This combination is particularly effective in reducing nitrogen oxides6 through selective catalytic reduction (SCR). The large surface area of TiO2 allows for optimal distribution of the active catalyst, enhancing the reaction efficiency.

| Catalyst Component | Function |

|---|---|

| TiO2 | Provides surface area |

| Vanadium Pentoxide | Converts NOx to N2 and H2O |

Advantages of Using TiO2 in Vehicle Systems

TiO2’s chemical stability and resistance to sulfur compounds make it an ideal choice for use in environments where other materials might degrade. Its ability to maintain performance over prolonged periods ensures that vehicles consistently meet emission standards. Moreover, the durability of TiO2-based systems contributes to longer service life7 and reduced maintenance costs.

Impact on Air Quality and Sustainability

By enhancing the efficiency of catalysts, TiO2 significantly reduces the emission of harmful nitrogen oxides, which are major contributors to urban smog and acid rain. This reduction plays a critical role in improving air quality and protecting ecosystems. Additionally, using TiO2 in vehicle emission systems aligns with global sustainability goals by promoting cleaner transportation solutions.

Future Prospects and Innovations

Research is ongoing to further optimize TiO2’s properties and explore its potential applications in emerging technologies, such as electric vehicles. Innovations could lead to even more effective emission reduction strategies, making TiO2 an indispensable part of future emission control solutions.

[claim claim=”TiO2 is used in catalytic converters.” istrue=”true” explanation=”TiO2 provides surface area for catalysts in catalytic converters.”]

[claim claim=”TiO2 degrades quickly in vehicle systems.” istrue=”false” explanation=”TiO2 is chemically stable and resists degradation over time.”]

Conclusion

TiO2’s role in exhaust gas treatment is vital for reducing emissions and improving air quality. As industries seek sustainable solutions, understanding TiO2’s capabilities can drive further innovation in pollution control technologies.

-

Learn how denitration catalyzers utilize TiO2 to reduce emissions.: Denitrification is the process in which some microorganisms couple respiratory ATP synthesis to the reduction of nitrate and nitrite, via the gaseous N oxide … ↩

-

Discover how TiO2 enhances catalyst performance and longevity.: The additions of promoters and support in titanium oxide catalysts improved their performances and reduced their stability. The bulk reduction state of TiO2 … ↩

-

Explore how TiO2 aids in reducing vehicle emissions effectively.: 100 ppm nano-TiO 2 added to 10 % of EGR, along with PI, can achieve the same or enhance better brake thermal efficiency (BTE) by 4.53 % than pure diesel. ↩

-

Learn how TiO2 aids in reducing harmful NOx emissions effectively.: This study revealed that NO x reduction can be realized through TiO 2 photocatalyst-infused coating in winter or cloudy days with a low solar altitude. ↩

-

Discover how industries gain efficiency with TiO2 catalyst use.: The TiO2 films composing of nanoparticles maintained the porous microstructure and represents excellent catalytic performance. The TiO2 nanoparticles, nanodots … ↩

-

Discover how TiO2 aids NOx conversion efficiently.: The titanium dioxide (TiO2) is one of the best transitional metal oxides catalysts for lower temperature CO oxidation. A small amount of TiO2 was deposited on … ↩

-

Learn why TiO2 leads to longer-lasting vehicle emissions systems.: Titanium dioxide is a crucial ingredient in helping to make sure that harmful emissions from vehicles and factories never make it into the air. ↩