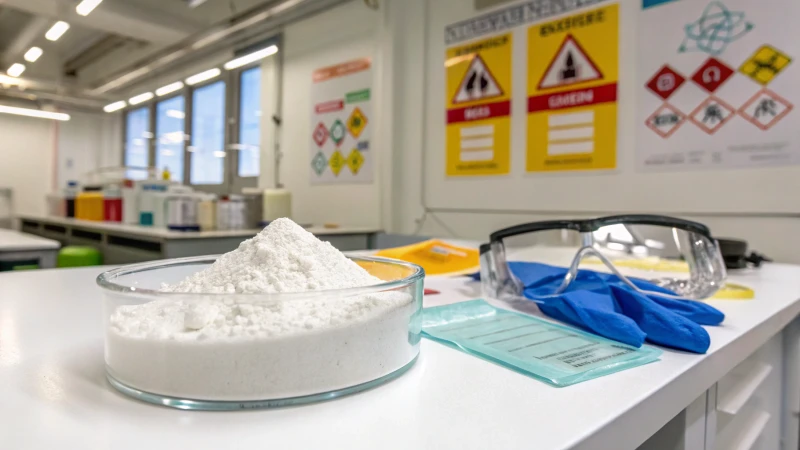

Titanium dioxide is a crucial component in coatings, known for its exceptional whiteness, hiding power, and durability. This pigment effectively scatters light to provide opacity and brightness while enhancing weather resistance. The choice between Anatase and Rutile types significantly impacts performance; Rutile is preferred for outdoor applications due to its superior properties. Understanding the nuances of titanium dioxide can lead to cost-effective solutions in paint manufacturing by reducing material usage without compromising quality. Its excellent dispersibility ensures smooth application and longevity of coatings across various industries including construction, plastics, and more.