Discover how titanium dioxide transforms rubber products from mundane to magnificent.

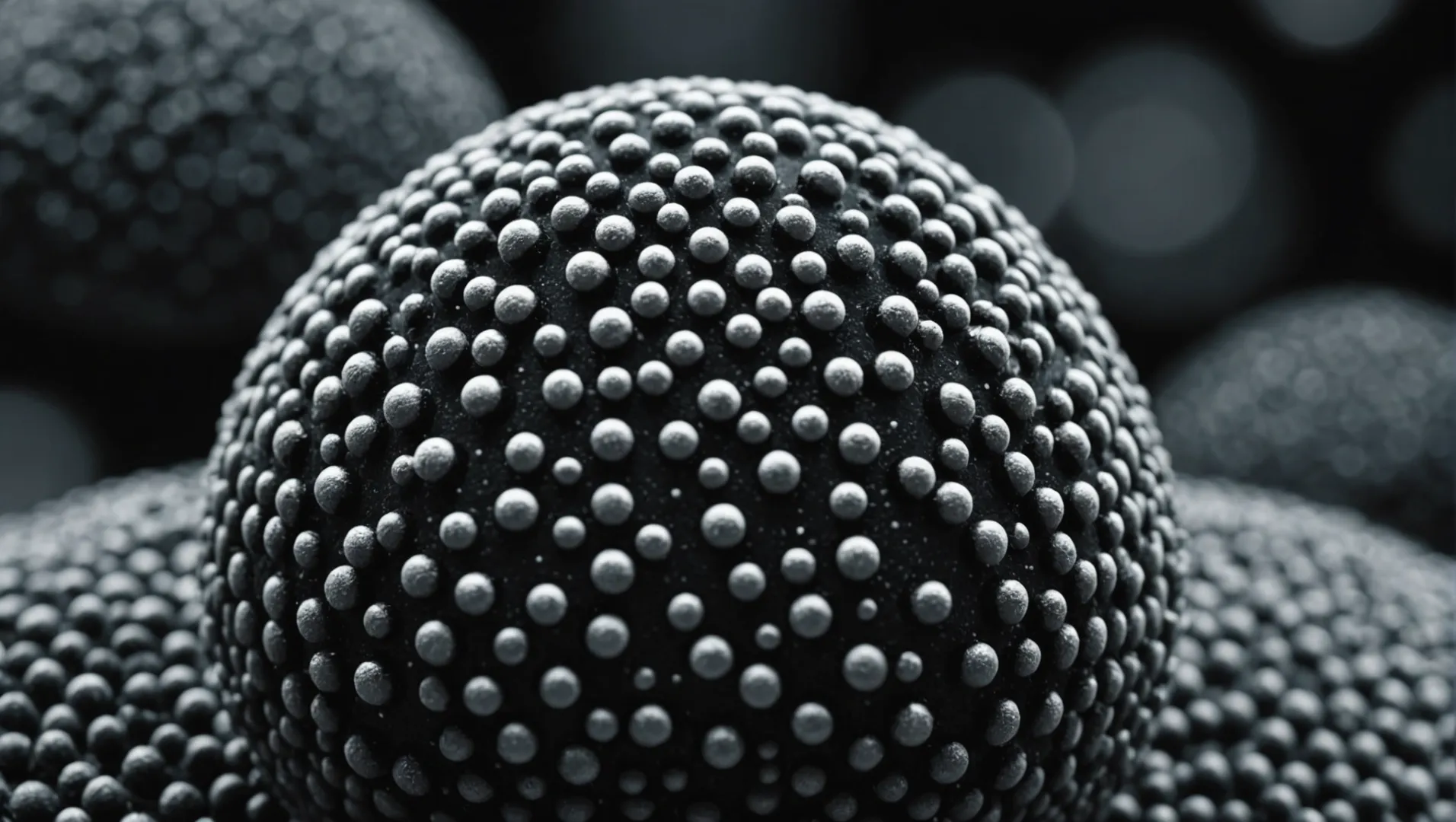

Titanium dioxide is utilized in the rubber industry primarily as a pigment and reinforcing agent. It enhances the whiteness and opacity of rubber products, improves mechanical properties like tensile strength, and provides UV resistance, making rubber more durable and aesthetically pleasing.

While titanium dioxide's initial benefits are clear, its comprehensive role in enhancing rubber products extends beyond basic functionality. In the following sections, we'll delve into the technicalities of its applications, explore industry insights, and reveal how this compound contributes to modern rubber manufacturing.

Titanium dioxide improves rubber's UV resistance.True

TiO₂ acts as a barrier, reflecting UV light and reducing degradation.

What Are the Mechanical Benefits of Titanium Dioxide in Rubber?

Explore how titanium dioxide enhances rubber's mechanical properties for superior performance.

Titanium dioxide improves rubber's tensile strength, tear resistance, and durability, making it ideal for diverse applications.

Enhancing Tensile Strength

One of the foremost mechanical benefits of incorporating titanium dioxide into rubber compounds is its ability to significantly enhance tensile strength. Tensile strength refers to the maximum amount of tensile (stretching) stress that a material can withstand before failure. In rubber products, higher tensile strength translates to better performance under stretching forces. When titanium dioxide is used as a filler, it forms a complex matrix with the rubber molecules, resulting in a stronger, more resilient material. This is particularly beneficial in applications such as automotive components and industrial belts1, where materials are regularly subjected to high stress levels.

Improving Tear Resistance

Tear resistance is another critical property that determines the durability and longevity of rubber products. By adding titanium dioxide to rubber formulations, manufacturers can achieve superior tear resistance. This improvement occurs because titanium dioxide particles distribute evenly throughout the rubber matrix, creating a more uniform structure that can better resist tearing forces. This property is especially valuable in products like tires and footwear soles2, where exposure to rough surfaces and mechanical abrasion is common.

Enhancing Overall Durability

Durability encompasses several mechanical attributes, including resilience to deformation, wear, and environmental factors. Titanium dioxide contributes to enhanced durability by acting as a robust reinforcing agent. It minimizes the rate of degradation due to mechanical stresses and environmental conditions like heat and UV exposure. The resultant durable rubber products are ideal for outdoor applications such as sealing gaskets3 and weather-resistant seals, ensuring long-lasting performance even in challenging environments.

Consideration of Other Additives

While titanium dioxide offers substantial mechanical benefits, its interaction with other additives should be considered for optimal performance. For instance, combining titanium dioxide with antioxidants or stabilizers can further enhance rubber's resistance to aging and environmental damage. Manufacturers often explore various formulations to balance mechanical properties and cost-effectiveness in producing high-quality rubber goods.

Titanium dioxide enhances rubber's tensile strength.True

It forms a complex matrix with rubber, increasing resilience.

Titanium dioxide reduces rubber's tear resistance.False

It actually improves tear resistance by creating a uniform structure.

How Does Titanium Dioxide Enhance UV Resistance in Rubber Products?

Titanium dioxide in rubber protects against UV damage, extending product lifespan significantly.

Titanium dioxide enhances UV resistance in rubber products by acting as a physical barrier that reflects and scatters ultraviolet light, thereby reducing degradation and prolonging the material's durability.

The Mechanism of UV Protection with Titanium Dioxide

Titanium dioxide (TiO₂) is a highly effective UV-blocking agent due to its ability to reflect and scatter ultraviolet light. This is primarily because of its high refractive index, which allows it to act as a physical barrier on the surface of rubber products. By preventing UV rays from penetrating and causing photochemical reactions, TiO₂ significantly reduces degradation processes such as cracking, fading, and loss of elasticity.

Benefits of Enhanced UV Resistance

The integration of TiO₂ into rubber compounds not only extends the lifespan of products but also maintains their aesthetic and mechanical properties over time. For outdoor applications like automotive tires or playground surfaces, this UV resistance is crucial. It ensures that rubber products remain functional and visually appealing despite prolonged exposure to sunlight.

A study on rubber formulations demonstrated that those containing TiO₂ exhibited far less discoloration and structural weakening compared to those without titanium dioxide in rubber studies4. These findings underline the material's efficacy in enhancing UV resistance and protecting against environmental wear and tear.

Industrial Applications and Considerations

Manufacturers across various sectors benefit from using TiO₂ in their rubber products. In industries where safety is paramount, such as automotive or aerospace, the material's ability to preserve the integrity of components under UV stress is invaluable. Moreover, the cost savings from reduced maintenance and replacements further highlight the economic advantages of using TiO₂.

When incorporating TiO₂, producers must consider the particle size distribution and concentration to optimize performance without compromising the mechanical properties of the rubber. Innovations in nanotechnology have led to developments in ultra-fine TiO₂ particles that provide superior UV protection while maintaining clarity and flexibility in transparent or translucent rubber products.

Titanium dioxide acts as a UV-blocking agent in rubber.True

Titanium dioxide reflects and scatters UV light, preventing degradation.

Rubber products with TiO₂ degrade faster under UV exposure.False

TiO₂ protects rubber from UV damage, extending its lifespan.

What Role Does Titanium Dioxide Play in Rubber Processability?

Uncover the secret ingredient that revolutionizes rubber manufacturing.

Titanium dioxide enhances rubber processability by improving flow properties, enabling smoother manufacturing. It aids in efficient shaping and molding of rubber products, reducing costs and enhancing production efficiency.

Improving Flow Properties

Titanium dioxide (TiO₂) significantly impacts the flow properties of rubber compounds during manufacturing. By enhancing these properties, TiO₂ enables the rubber material to flow more smoothly through the molds, facilitating easier shaping and molding. This improvement in flow dynamics is crucial for ensuring that the final product meets precise specifications, thereby enhancing quality control and consistency across production batches.

Enhancing Efficiency in Production

With better processability, manufacturers experience reduced cycle times in production. This not only increases the throughput of manufacturing lines but also decreases energy consumption per unit produced. For example, in industries producing large volumes of rubber items, such as automotive parts or consumer goods, this can lead to substantial cost savings. The efficient dispersion of TiO₂ ensures that these benefits are realized without compromising the mechanical properties of the final product.

Cost-Effectiveness and Sustainability

The use of TiO₂ contributes to a more cost-effective manufacturing process. By enhancing the flow and moldability of rubber, the likelihood of defects is minimized, reducing waste and rework. Moreover, as an eco-friendly additive, TiO₂ aligns with sustainable manufacturing practices. It helps manufacturers produce durable goods that require less frequent replacement, thus promoting a reduction in raw material consumption over time.

For further insights into the eco-friendly aspects of TiO₂ and its role in sustainable production practices, explore eco-friendly manufacturing trends5.

Titanium dioxide improves rubber flow properties.True

TiO₂ enhances flow properties, aiding in shaping and molding.

Using TiO₂ increases rubber manufacturing costs.False

TiO₂ reduces costs by improving processability and efficiency.

Why is Titanium Dioxide Considered Eco-Friendly in Rubber Manufacturing?

Explore why titanium dioxide is hailed as an eco-friendly choice in rubber manufacturing.

Titanium dioxide is considered eco-friendly due to its non-toxic nature, UV protection capabilities, and contribution to product longevity, which reduces waste. Its use aligns with sustainable manufacturing practices by minimizing environmental impact while enhancing product performance.

Titanium Dioxide: A Non-Toxic Choice

In rubber manufacturing, choosing materials that do not harm the environment is crucial. Titanium dioxide (TiO₂) stands out for its non-toxic properties. Unlike some additives that can leach harmful chemicals, TiO₂ remains inert, ensuring it does not contribute to environmental pollution during the production process or the lifecycle of the product.

Contributing to Longevity and Reduced Waste

One of the most significant environmental benefits of using TiO₂ in rubber is its ability to enhance product durability. By providing superior UV resistance6, TiO₂ helps rubber products withstand prolonged exposure to sunlight without degrading. This resistance to UV damage means products last longer and need less frequent replacement, ultimately reducing waste.

Additionally, TiO₂ improves the mechanical properties of rubber, such as tensile strength and tear resistance. Enhanced durability leads to fewer defective products and less material waste during manufacturing.

Aligning with Sustainable Manufacturing Practices

Manufacturers are increasingly focusing on sustainability, and TiO₂ aligns perfectly with these goals. Its ability to improve processability means less energy is consumed during production. The ease of dispersion in rubber compounds allows for more efficient manufacturing, cutting down on resource use and emissions.

Moreover, by opting for TiO₂, manufacturers can produce high-quality products without relying on more harmful substances. This shift not only meets consumer demand for sustainable products but also helps companies adhere to stricter environmental regulations.

Overall, titanium dioxide serves as a critical component in creating eco-friendly rubber products. Its role in enhancing durability, reducing waste, and aligning with sustainable practices makes it an essential part of modern rubber manufacturing strategies.

Titanium dioxide is non-toxic in rubber manufacturing.True

TiO₂ is inert and does not leach harmful chemicals, ensuring safety.

Titanium dioxide reduces rubber product waste.True

TiO₂ enhances durability and UV resistance, extending product life.

Conclusion

Titanium dioxide's multifaceted role in the rubber industry enhances product durability, aesthetics, and processability. Embracing this compound can lead to more efficient manufacturing and longer-lasting products. Consider integrating TiO₂ for optimal performance and sustainability.

-

Learn about how tensile strength benefits automotive rubber parts.: A rubber tensile strength chart is a graphical representation of the tensile strength values of different types of rubber under various conditions. ↩

-

Understand why tear resistance is crucial for durable footwear.: You can say that usually footwear application should exceed a tear strength of 15 N/mm to succeed the tear strength test. The longer the ... ↩

-

Discover how sealing gaskets withstand environmental stresses.: According to experts, choosing the right seal for each specific job is crucial to the overall safety and performance of seals in hazardous pump applications. ↩

-

Explore detailed studies confirming titanium dioxide's efficacy in enhancing UV resistance.: Titanium dioxide is widely used in plastic production to improve the plastics environmental resistance and has a high ability to absorb UV irradiation ( ... ↩

-

Learn how TiO₂ supports sustainable production, reducing environmental impact.: TiO 2 is not only a pigment but an enabler for longevity and resilience. It transforms ordinary plastics into durable, reliable, and eco-friendly solutions. ↩

-

Learn about TiO₂'s UV protection properties and its eco-friendly impact.: Titanium dioxide (TiO₂) is a mineral filter which provides protection in the UVB and UVA range. While some organic filters cover only certain wavelengths, TiO2 ... ↩